Jopa MX Wear 2015

A Brand, A

A Brand, A passionFifteen years of passionate work experienced with absolutededication and a great desire to aim higher are the main ingredientswhich allowed Locatelli S.p.a to become the beautifulreality my family, my staff and I are so proud of.teamspiritAbility,competence, creativity, commitment, talent and teamwork are the weapons the Airoh team uses to take the field everyday to manufacture top level products that meet the higheststandards of quality, safety and comfort. Each of our helmetsis the result of the profound and stimulating team spirit that,characterizing our staff, involves all its members in the pursuitof absolute perfection.A Brand, A PassionMy family is at the very heart of my company, and it gives me great pleasure to see the pride that links usall to the Airoh brand and its future. It is a spirit that has grown strong over the years, and which takes ourdreams through to a prestigious, unique reality every single day where results abound and extraordinarythresholds are reached.experience and innovationDay after day Airoh increases its experience and know-how byinvesting in research, development, technology and innovation,as well as supporting all its talented and blazoned champions inany motoring sport. Technicians and athletes concur togetherin the continuous improvement of all the products of this 100%Italian enterprise- the former in laboratories, the latter on thecircuits- in order to always ensure a prompt and effective responseto even the most demanding requests.Antonio Locatelli -Owner Airoh44

step 1 engineeringBefore taking shape, each Airoh helmet is developed for a long time by the AirohStaff together with the industrial designer and carefully studied as well in theplanning phase and selection of the materials. The first samples are made on theoperational feedbacks coming from our testers and professional riders, who areentrusted with the task of evaluate every feature of our helmets, wearing them onthe racetrack and in their daily commutes. Their always precious ratings allowthe company to re-calibrate and improve the performances of its final products.step 2 wind tunnelEach Airoh helmet is tested in the wind tunnel by highly specialized technicians,who evaluate their aerodynamics according to specific benchmarks, in order tocharacterize them with the maximum internal ventilation and ergonomics degreesever.step 3 moldingThe outer shells of the Airoh helmets in thermoplastic take shape through a sophisticatedfusion process, which perfectly combine a set of polymers of polycarbonatein special injection molds; the models in carbon fiber and Kevlar areinstead the final outcome of a meticulous handmade process stratified as per theMulti Axial system. The inner EPS of our products is obtained through a steammolding process at high temperatures. The Airoh visors are printed and thentreated with scratch resistant processes.step 4 painting and sewingThe outer shell of every Airoh helmet is painted and treated with a UV filter for fulfillingthe highest standards of quality and design, in the complete respect of theenvironment: endurance, durability and colour luster are guaranteed over time.The graphics of the outer shells are made by the manual application of decals,through a scrupulous and careful process able to give to any Airoh helmet theunique design that sets it apart. The latest-generation inner fabrics are highly transpiringand sewn by experts, as proof of the great attention that the enterprise hasalways paid to quality.step 5 assemblingAt the main Locatelli S.p.A. factory is placed the accurate assembly of the partswhich make up an Airoh helmet. Before and during this process, completely executedby hand by skilled personnel, each component is meticulously controlledand possibly discarded if presents even the slightest imperfection.step 6 testResearch, development and prototyping are at the heart of every Airoh brandedproject. Prototypes and final products are always undergone to extensive and accuratetests able to prove their complete uniformity with the strictest parametersimposed by the national and international standards, to ensure maximum safetyboth to our professional riders and customers.45

- Seite 3 und 4: index2. Jopa MX42. airoh58. shiro62

- Seite 6 und 7: Jopa MXDutch hand madein-house prod

- Seite 8 und 9: Jopa MXPRODUCTSRain jerseyThe ‘Ra

- Seite 10 und 11: Jopa MXour commitmentswhy jopa is y

- Seite 12 und 13: Jopa MXjopa mx sizingjopa mx jersey

- Seite 14 und 15: Jopa MX951 - Red/White955 - Black/G

- Seite 16 und 17: Jopa MX954 - Blue/Orange953 - Blue/

- Seite 18 und 19: Jopa MX940 - Black/Orange941 - Blac

- Seite 20 und 21: Jopa MX945 - Fluor/Black/Blue946 -

- Seite 22 und 23: Jopa MX20

- Seite 24 und 25: Jopa MX976 - Red/Yellow974 - Black/

- Seite 26 und 27: Jopa MX960 - Red/Blue958 - Green/Bl

- Seite 28 und 29: Jopa MX26

- Seite 30 und 31: Jopa MX973 - Black/Turquase972 - Bl

- Seite 32 und 33: Jopa MX970 - Black/Red/Blue968 - Bl

- Seite 34 und 35: Jopa MX965 - Black/Green977 - Black

- Seite 36 und 37: Jopa MXlocust II Scrum Red/BlueXS -

- Seite 38 und 39: Jopa MX36

- Seite 40 und 41: Jopa MXmx-6 glovesjopa mx glovesMX-

- Seite 42 und 43: Jopa MXlegend glovesjopa mx glovesA

- Seite 48 und 49: airoh offroadaviator 2.1 six days 2

- Seite 50 und 51: airoh offroadterminator 2.1 Rocksta

- Seite 52 und 53: airoh offroadJumper TC15XS - XL 156

- Seite 54 und 55: airoh offroadPatented Space Saver S

- Seite 56 und 57: airoh offroadevergreen color whiteX

- Seite 58 und 59: airoh offroadfighter defenderXS - X

- Seite 60 und 61: shiro offroadSHIRO HELMETS, S.A. Fo

- Seite 62 und 63: shiro offroadMX-734 BRavooffroad he

- Seite 66 und 67: over 50 years of experienceEvery da

- Seite 68: sidi offroadtechnical comfortCrossf

- Seite 71 und 72: sidi offroadcrossfire 2 GRey/Black/

- Seite 73 und 74: sidi offroadcrossfire 2 SRS white/o

- Seite 75 und 76: aguedaoffroad bootsfeaturesIn searc

- Seite 77 und 78: sparepartsoffroad bootssidi offroad

- Seite 79: omeganeck bracesThe Omega brace was

- Seite 83 und 84: pro shirt XVforcefield protectionfe

- Seite 85 und 86: contakt shortsforcefield protection

- Seite 87 und 88: corax jacketzandona protectionfeatu

- Seite 89: kneeprotector deluxeprotectionkneep

- Seite 93 und 94: ip n roll colossus mirrorrip ‘n

- Seite 95 und 96:

Rip ‘N’ Rollhybrid graphic supe

- Seite 97 und 98:

Replacement Coversrip ‘n’roll a

- Seite 99 und 100:

scott split OTGscott mx gogglesfeat

- Seite 101 und 102:

wind warriorScott accessoriessweath

- Seite 103 und 104:

€ 6,9590100 - 901flippers€ 6,95

- Seite 105 und 106:

handle barpad nylonaccessorieshandl

- Seite 107 und 108:

105Jopa MX

- Seite 109 und 110:

scale models 1:6 standard99973-6-10

- Seite 111 und 112:

109

- Seite 113 und 114:

custom mx gearTake a design of our

- Seite 115 und 116:

dakar jacketfully custom teamwearpa

- Seite 117 und 118:

partly customizable productsJust ne

- Seite 119 und 120:

117teamwear

- Seite 121 und 122:

fleece vestteamwear100% Polyester32

- Seite 123 und 124:

Soft Shell jacket gateJAcketteamwea

- Seite 125 und 126:

Traffic controller Vestteamwear100%

- Seite 127 und 128:

teamwearThanks for helping!Photosho

Unangemessen

Laden...

Magazin per E-Mail verschicken

Laden...

Einbetten

Laden...

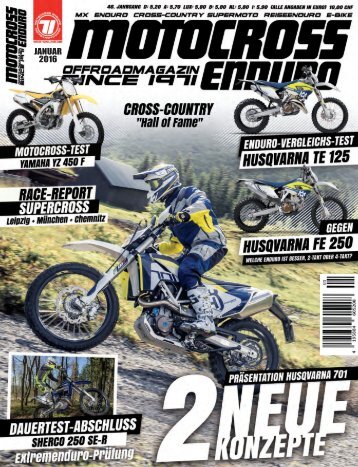

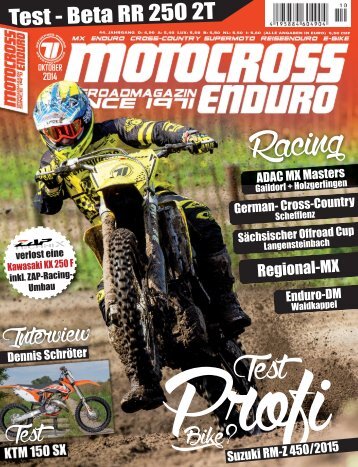

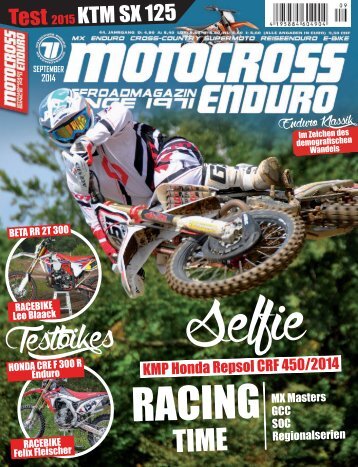

Motocross Enduro / Ausgaben 2014-2022

Motocross Enduro | Ausgaben 2014-2022

Röntgenstraße 4

63755 Alzenau

Tel. 06023 91782-86

Kontakt

Datenschutz

www.ziegler-verlag.de

09661 Rossau/Sachsen

Hauptstraße 56

Kontakt

www.mce-online.de